ATTRITOR MILL

HOW IT WORKS

ATTRITOR MILL is an innovative technology – covered by patents – designed to treat different types of waste, through a mechano-physical action that alters the waste structure, with a radical improvement in output.

ATTRITOR MILL is highly versatile and can be tailored to obtain functional outputs for a variety of uses:

RDF - END OF WAISTE

RDF – FROM ONE FLOW PROCESSING (UNSORTED WASTE)

ACCELERATION OF BIO-STABILIZATION

OPTIMISATION OF FEED FOR BIODIGESTERS

VERSATILITY

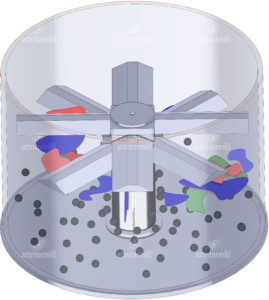

The ATTRITOR MILL system consists of several milling chambers that can also be operated individually and integrated to achieve the most suitable quantity requirement for each operator.

Depending on the waste to be processed and the desired output, the ATTRITOR MILL chambers can be equipped either with a system of grinding masses or with a hybrid system combining the action of blades and grinding masses.

EFFECTS OF TREATMENT WITH ATTRITOR MILL ON WASTE

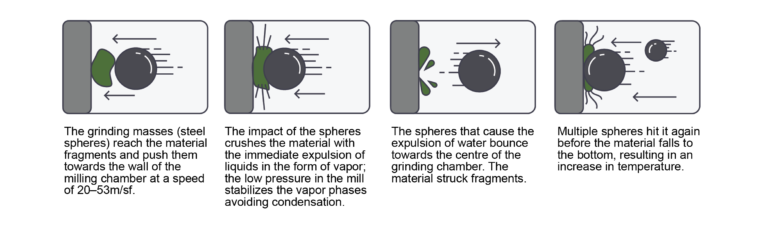

GRINDIND MASSES MILL

ATTRITOR MILL is a new-generation grinding system that provides greater efficiency in reducing the size of materials while minimizing waste and the energy required for the process. This technology is particularly suitable for processing materials of high hardness or brittleness, enabling Operators to improve the quality of their products while saving valuable resources.

BLADES + GRINDING MASSES MILL

ATTRITOR MILL-HYBRID is a combined system that stands out for its versatility. It is ideal for shredding a wide range of materials up to 250 mm in size, avoiding a secondary shredder to prepare the waste to be refined.

In the hybrid version, the grinding chambers are supplemented with a blade system upstream of the section in which the grinding masses operate.

ATTRITOR MILL

APPLICATION

UNSORTED WASTE

ATTRITOR MILL is the only system to micronize single-stream unsorted waste for RDF production.

DRY WASTE

The output processed with ATTRITOR MILL, as far as dry waste is concerned, is classified as RDF-End of Waste (according to UNI EN 15359/2011) with a size of 10-15mm, to be delivered to specific energy production plants and thus ceasing to be waste (EoW).

RDF-END OF WASTE

RDF-End of Waste is where solid waste ceases to be considered “waste” and becomes an alternative source of energy, thanks to rigorous selection, transformation and quality control processes that ensure RDF meets the highest environmental standards, acquiring “End of Waste” status. RDF-EoW can be used as fuel at Cement Plants, Thermal Power Plants and Steel Mills, contributing to the production of clean and sustainable energy. This innovative approach favors the reduction of waste going to landfills and promotes the transition to a circular economy.

ORGANIC WASTE

In the processing of organic waste – both from separate collection, and from mechanical sorting – ATTRITOR MILL can be set up with different processing solutions in order to achieve the desired output.

STABILIZATION

The extremely fast increase in pressure and temperature of the particles treated with ATTRITOR MILL promotes stabilization of the waste, reducing the processing time to obtain a stable material. This results from the thermal and pressure stress induced on the individual bacterial colonies and, at the same time, the reduction in the amount of water and nutrients available for their proliferation.

PREPARING MATERIAL FOR BIODIGESTERS

The action of ATTRITOR MILL, involves increasing the surface area of the waste and activating the mesophilic phase (37-40°C), favouring and accelerating the release of methanogenic gases.

In addition, ATTRITOR MILL, used to treat the solid residue of biodigesters, reduces odour and moisture emissions and enables the waste to be sent to energy recovery plants.

ATTRITOR MILL EXCLUSIVE DEALERS

Our network of exclusive dealers is a key partner in the deployment of this cutting-edge waste treatment technology. We work closely with these selected companies, granting them exclusivity to offer and service our innovative machinery in their respective markets.

COMMERCIAL NETWORK

The sales network ensures coverage of major markets. Explore our network of exclusive distributors and business partners.

Are you interested in joining the ATTRITOR MILL network?